Overview

NF Forgings' Foundry Division is a CLASS “A” certified facility, accredited by the Indian Registrar of Shipping (IRClass) for marine castings. Backed by robust infrastructure and quality assurance systems, the division delivers high-precision cast components for sectors including railways, public sector units, and industrial applications.

With an installed monthly capacity of 2000 MT, the foundry specializes in large-scale and custom casting solutions, conforming to IS:12117 standards. The division is equipped with advanced electric arc and induction furnaces, automated moulding lines, and extensive heat treatment setups. Quality is ensured through a NABL-accredited lab with comprehensive non-destructive and destructive testing capabilities.

Advanced Furnaces

3 electric arc (5.0 MT each) + 1 induction (3.5 MT).Automated Moulding

Green sand line (1300×1100×350 mm) + no-bake plants (20 & 30 MT/hr).Heat Treatment

7 PLC-controlled furnaces (5–15 MT) with quenching systems.In-House Testing

NABL-certified lab with full NDT & destructive testing suite.Precision QA

Microstructure analysis for material integrity and consistency.

Types of Metal Crash Barriers

Engineered for optimal roadside safety across varying traffic conditions and structural layouts.

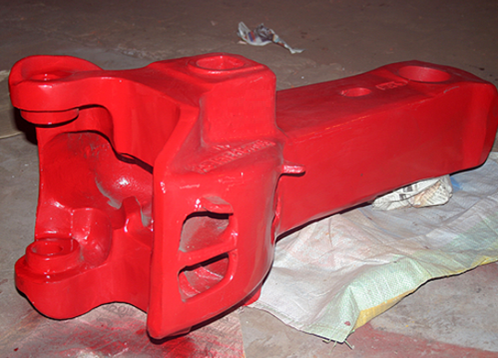

COUPLER BODY

Main structural part connecting railcars with robust material strength.

KNUCKLE

Pivoting component of the coupling system enabling articulation.

YOKE

Transfers draft and buff loads from the coupler to the wagon body.

STRIKER

Component that resists buffing loads during coupling impacts.

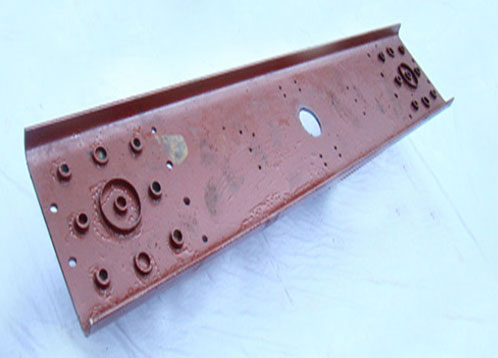

YOKE PIN SUPPORT PLATE

Provides secure mounting base for yoke pin assembly.

BACKSTOP

Prevents rearward movement of coupler under impact.

SPRING PLANK

Load bearing member in bogie structure supporting springs.

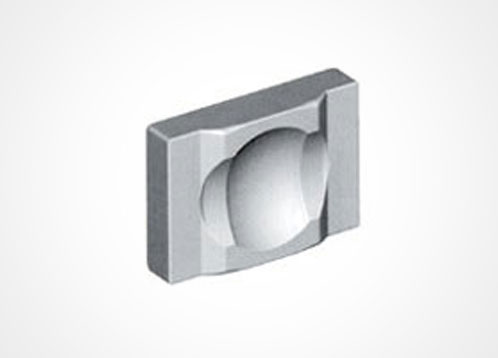

SPHERICAL CENTRE PIVOT TOP & BOTTOM

Ensures rotational movement of bogie under the wagon.

SPHERICAL CENTRE PIVOT TOP & BOTTOM

Ensures rotational movement of bogie under the wagon.

HIGH CAPACITY DRAFT GEAR WITH FOLLOWER

Absorbs impact energy during train operations and coupling.

HIGH CAPACITY DRAFT GEAR WITH FOLLOWER

Secondary draft gear variant with optimized impact control.

H - TYPE HIGH TENSILE TIGHT LOCK COUPLER

Provides high-strength coupling for demanding rail operations.

COUPLER BODY ASSEMBLY

Complete coupling system assembly for railcars.

CAST MANGANESE STEEL CROSSING

Critical rail turnout part ensuring rail vehicle redirection.

YOKE PIN

Secures the yoke and allows pivotal movement.

KNUCKLE PIN

Locks the knuckle into position during coupling.

ALL TYPES OF LINERS

Metal liners used to ensure smooth rail wheel transition.

MYANMAR COUPLER ASSEMBLY

Customized coupler assembly for Myanmar rail systems.